Port:Qingdao,Shanghai,Ningbo,Tianjin,Guangzhou,Yiwu etc

Payment Terms:L/C,T/T

Features:

Features:1. This model is one of classic and best selling cnc router, made of thickness square tube welded bed, imported square rail and high speeding stepper motor & driver. It can do cutting and engraving many materials, such as MDF, Acrylic, wood, PVC, etc. It’s widely used in advertising and woodworking industries.

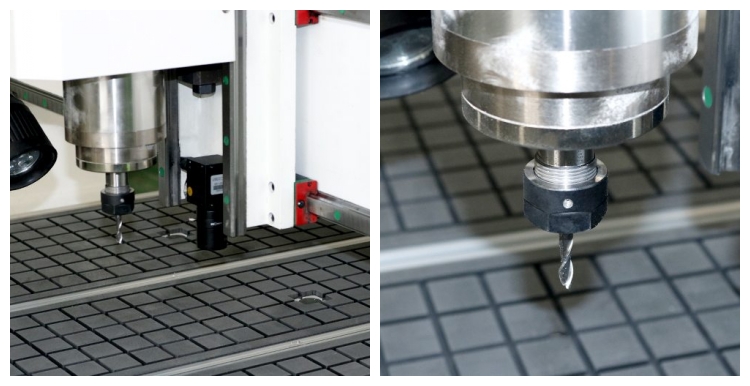

2.With China Well-known brands stepper motors and drivers, Hiwin linear guide rail, XY axis gear and rack transmission,Z axis TBI higher precision Ball Screws, ensure fast speed, big loading capacity, low noise, and longer time working;

3. Professional NC-Studio / Richauto DSP Panel /Mach3 /NK105 control system, Air cooling spindle 3.5KW or 6KW, long working life, low noise, strong cutting ability.

4.Vacuum and T-slot combined worktable can both absorb big materials by vacuum power and fix small materials by clamps.

5. Electronic control components from famous brand in China such as CHNT / DELIXI company.

6. Auto Oil-filling System for gularly maintenance (lubricating) is so convenient to use.

1. Wood industry: wood furniture making, 3d wood relief carving, wooden craftwork production Speakers, game consoles cabinets, computer tables, sewing machine table etc.

2. Advertising products industry: 3D letters sign making, acrylic cutting and engraving.

3. Board processing industry: insulation piece, acrylic board, plastic chemical products, PCB, compact grade laminate, ABS, PP, PE and other cementitious mixtures’s milling process.

4. Decoration industry: folding screen, wave plates, advertising boards, sign making and logo’s processing.

5. Arts & Crafts industries: Engrave on artificial stones, woods, bamboos, marbles.

6. Processing material: engraving, milling and cutting processing for acrylic, PVC, artificial stones plastics and soft metal sheets and so on.

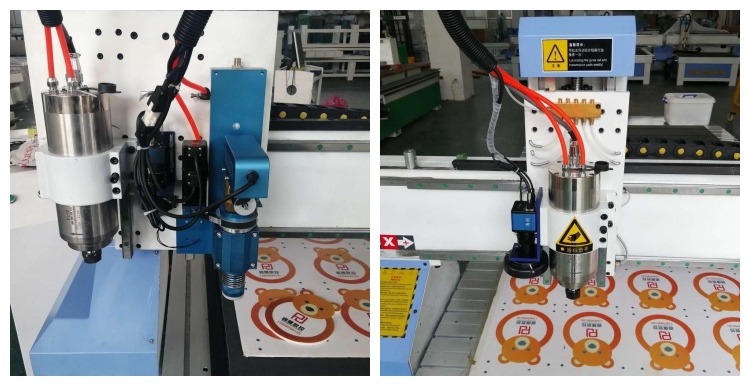

Auto Contour cutting machine CNC router

CCD intelligent edge patrol cutting machine adopts one-key quick switching dual-system control mode, not only has traditional plane cutting, 3D embossing and other functions, but also suitable for patrolling and cutting of logo plates and image contour maps; it can process KT boards, PVC , Acrylic and other medium hardness plates.

The CCD visual cutting system adopts Japanese industrial cameras with strong anti-interference ability, fast recognition speed and high efficiency. Provide users with solutions that meet the requirements of two-point positioning, four-point positioning, and automatic edge finding and cutting. It is suitable for trademarks, pictures and other occasions that require intelligent recognition and cutting. The recognition and cutting speed is fast, and the operation is simple and convenient.

Avoid the problems of time-consuming and laborious traditional manual positioning and waste products caused by board deviation;

It can recognize and cut large-area graphics, and one person can take care of multiple devices at the same time, which saves a lot of labor, electricity and space, and is cost-effective;

Automatic edge recognition, no need to output engraving path, template cutting, puzzle cutting, strong recognition ability, fast positioning speed and high positioning accuracy;

Support feature matching, two-point positioning, multi-template positioning, contour extraction and other positioning methods;

Graphic editing, typesetting, control and output are completed in one stop;

Support multiple source data formats: BMP, AL, PLT, DXF, DST, etc.;

Accurate cutting, fast cutting speed, no missing mark, no random cutting phenomenon, high cutting efficiency, large output;

The powerful vacuum adsorption system can meet the needs of various processing techniques;

One machine for multiple purposes, in addition to the side patrol function, it can also carry out sign engraving processing, pvc, acrylic engraving and cutting

It is used for high-precision, high-efficiency patrolling and cutting of plate printing patterns.

Suitable for high-efficiency production of various woodworking products. Advertising signs, acrylic cutting. Blister molding and large-scale cutting, and can engrave iron, copper, aluminum, plastic board, wood board or other non-metallic materials.

Model | 1325 |

Working Size | 1300x2500mm |

Frame | Welded Structure |

Guide Rails | Square Rails Hiwin 20mm |

Transmission | X Y Rack gears Z TBI Ball screw |

Motor | Stepper motor & driver (Optional Hybrid servo) |

Cabinet | Independent Computer Cabinet |

Control system | NC-Studio / Rich auto DSP Panel /Mach3 +AWC |

Moving Speed | Max 25m/ min |

Engraving Speed | Max 20m/ min |

Spindle | 3.5KW air cooling (Optional 4.5KW,5.5KW,6KW) |

Spindle speed | 0-18000 rpm |

Table | T-slot & Vacuum |

Vacuum pump | 7.5kw Vaccum pump |

Dust Collecter | 3kw |

Lubrication | Centralized Lubrication |

Software | Type3 / ARTCAM/ Ucancam |

Working Voltage | 220V/380V,±10%, 50Hz/60Hz |

Packaging And Shipment :

Whole film packaging machine

Anti-collision package edge

Fumigation-free plywood wooden box with iron binding belt

According to customer's requirements for loading the whole container or LCL at domestic port.

For any questions and inquiries, please contact with us freely!